Sun dried tomatoes exemplify the ideal ingredient for today’s fresh and processed food products.

The Valley Sun Products, Inc. team has over 25 years of experience in production and quality of sun drying tomatoes. They are under the umbrella of the Morning Star family, which prides itself on being “everything tomato” – and Valley Sun Products plays a key role in that definition.

Valley Sun Products contracts with the largest tomato grower/processor in the Central California area during December of each year. This assures that the best tomatoes are planted for drying. They observe strict State and Federal safety guidelines in growing the tomatoes to assure they are of the finest quality and that they conform to Valley Sun Product’s rigorous requirements.

Products

Sun Dried Tomatoes

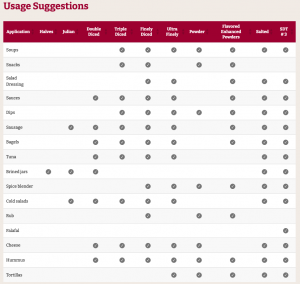

When food manufacturers want intense tomato flavor, healthful nutrition profile, versatility, convenience, and value-added appeal , they know to specify sun-dried tomatoes. Sun-dried tomatoes offer end-users a year-round, reliable source for a pleasing tomato identity and taste. Valley Sun Products offers a wide variety of traditional sun-dried tomato products:

• Halves

• Julienne

• Double Diced

• Triple Diced

• Finely Diced

• Ultra Finely Diced

Sun Dried Tomato Powders

Valley Sun Products’ Roma tomatoes are harvested at the peak of ripeness and milled to create a smooth product for use in:

• Sauces

• Soup

• Pasta Dough

• Dry Mixes

• Toppings

• Complete Vertical Integration Process

Powders are a great way to add Umami, color and flavor to any dish.

Usages

Food manufacturers know to specify sun-dried tomatoes when intense tomato flavor, healthful nutrition profile, versatility, convenience, and value-added appeal head the list of product criteria. Moreover, sun-dried tomatoes offer end-users a year-round, reliable source for a pleasing tomato identity and taste.

Process

Sun drying is one of mankind’s oldest preservative techniques. It was used in ancient Egypt and Mesopotamia. It is a slow, gentle process whose benefits more than compensate for its time-intensive nature – especially when compared to modern mechanical drying methods.

Tomatoes, which contain more moisture than an average stone fruit, must bask in the sun for a period of 4 to 10 days to develop the characteristics prized by culinary experts and gourmets. The changes in Central California Valley temperatures from the low 100’s during the day to a cooler 70-80° at night, ensures that the tomatoes dry very gradually.

The difference between sun dried and mechanical dehydration is important. Sun dried tomatoes must be dried over several days by the sun’s natural heat. Dehydrated or tunnel dried tomatoes may be artificially dried at temperatures up to 200° F. in a matter of hours, a process which may burn or scorch the fragile tomato.

• The process begins with a twelve-hour exposure to the burning of elemental sulfur, a substance which naturally occurs in nature, and which is used in the processing of fine wines and balsamic vinegars. The sulfur ensures that the tomatoes retain their natural brilliant red color and a sweet intense flavor; and discourages rodents, insects and birds from the area around the drying yard.

• Valley Sun Products places their tomato drying trays on a fully paved dry yard, surrounded by fencing. The tomatoes are further protected from intrusion by foreign material using carefully placed canvas wind breaks. The perimeter of the yard has a metal rodent barrier extending from below ground level to approximately three feet high. The facility is also serviced weekly by a pest control program.

• They have an on-site laboratory, and their product is checked throughout the drying and packing processes for compliance with their high-quality standards. Special attention is paid to the texture of the tomato, removing them from the trays when sufficiently dry but retaining a soft pliable texture.

• Valley Sun Products tomatoes are inspected by the Dried Fruit Association (DFA). They average a score of over 1800 out of 2000 possible points.

The Highest Quality Control Standards in the Business

Valley Sun Products’ quality control standards set it apart from the competition, exceeding the necessary requirements set by the FDA. Features of the Valley Sun Products quality control include:

• Onsite full-time QC staff.

• Onsite laboratory equipped to test moisture levels, pH, sulfite concentration, salt concentration, yeast and mold.

• Local microbiological testing laboratory: quick and accurate test results.

• Established HACCP program in place

• QA Manager HACCP Certified

• Regular verifications of control points to ensure product safety

• Regular QC checks in place to ensure specification compliance and product quality

• Established GMP program with monthly in-house inspections to ensure sanitary and food safety practices.

• Over 20 years of combined staff QC experience.

• Tailored Certificate of Analysis (CoA) to customer needs.

Packaging

Valley Sun Products’ sun-dried tomatoes are available in a variety of packaging.

• 25# Case

• 30# Case

• 450# Fiber Tote

Call Burley Foods at (952) 943-1970 or contact your account manager to find out more about Valley Sun Products’ sun-dried tomatoes. Request samples and schedule a demonstration.